Copper vs. Aluminum Cables: Which is Best for UAE Projects?

Discover whether copper or aluminum cables suit your UAE project. Learn differences, benefits, and installation factors from a top cable supplier in UAE.

Introduction

Choosing the appropriate electrical cable is essential for both performance and safety in the UAE's quickly expanding infrastructure landscape.With extreme temperatures, strict building regulations, and high energy demands, engineers and contractors must choose carefully between copper and aluminum conductors. Working with a knowledgeable cable supplier in UAE ensures access to the right type of cable for every applicationfrom high-rise towers in Dubai to industrial installations in Abu Dhabi.

This article provides an in-depth comparison of copper and aluminum cables, exploring their strengths, limitations, and suitability for UAE construction environments.

Understanding the Basics: Copper and Aluminum Cables

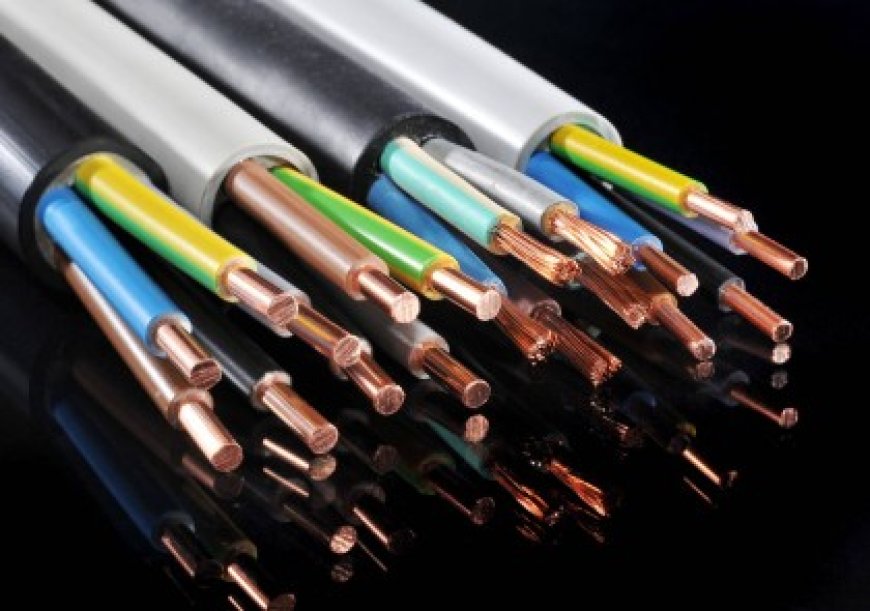

Copper Cables

Copper has long been considered the standard for electrical wiring due to its excellent conductivity and mechanical strength. It is widely used in residential, commercial, and industrial projects where efficiency and durability are key.

Aluminum Cables

Aluminum cables offer a lighter and more cost-effective alternative to copper. While slightly less conductive, modern aluminum cables have improved insulation and design, making them a viable option for many applications.

Key Factors to Consider When Choosing Between Copper and Aluminum

1. Conductivity

Copper conducts electricity better than aluminum.This implies that the same current can be carried by a smaller copper cable as by a larger aluminum cable. In environments where space is limited, copper may be the more practical choice.

2. Weight and Flexibility

Aluminum is about 30% the weight of copper, making it easier to handle, transport, and installparticularly in large projects like substations or long-distance power distribution lines.

3. Durability and Strength

Copper offers higher tensile strength and better resistance to breakage, making it ideal for installations that require frequent handling or exposure to mechanical stress. It also resists corrosion better in most environments.

4. Thermal Expansion

Aluminum expands more than copper when heated. In the UAEs hot climate, this can lead to loosening at terminals over time if not properly installed. Special connectors and frequent checks are needed for aluminum installations.

5. Installation Considerations

Aluminum requires more care during installation. Overheating and fire hazards might result from improper terminations. Conversely, copper cables are more lenient and need less safety measures.

Application Suitability in UAE Construction Projects

Copper Cables Are Ideal For:

-

High-rise buildings where space efficiency is critical

-

Emergency systems and fire-resistant installations

-

Data centers or sensitive electrical systems

-

Areas with fluctuating or extreme temperatures

Aluminum Cables Are Suitable For:

-

Long-distance underground or overhead power distribution

-

Large industrial or utility projects

-

Locations where weight is a limiting factor

-

Temporary power setups or modular buildings

Environmental Considerations in the UAE

The UAEs climate presents challenges such as intense heat, sandstorms, and humidity. Copper's corrosion resistance and lower thermal expansion make it more stable in such environments. However, with proper insulation and sealing techniques, aluminum can also perform reliably.

Choosing the right insulation typelike XLPE or LSZHenhances protection for both copper and aluminum in outdoor or high-temperature areas.

Safety and Compliance

Both copper and aluminum cables must comply with local standards such as:

-

UAE Fire & Life Safety Code

-

DEWA (Dubai Electricity and Water Authority) regulations

-

Abu Dhabi Distribution Company (ADDC) guidelines

Working with a certified cable supplier in UAE helps ensure all products meet these regulations and come with proper documentation for project approvals.

Maintenance and Longevity

Copper cables generally require less maintenance and have a longer lifespan due to better durability and resistance to thermal cycling. Aluminum systems, if maintained well and installed using approved connectors, can also offer excellent performance.

For mission-critical systems such as emergency lighting, elevators, or fire alarms, copper is usually preferred due to its superior reliability.

Summary: Which One Should You Choose?

| Criteria | Copper | Aluminum |

|---|---|---|

| Conductivity | Higher | Lower |

| Weight | Heavier | Lighter |

| Installation | Easier | Requires special care |

| Thermal Expansion | Lower | Higher |

| Durability | Excellent | Moderate |

| Cost-efficiency | Moderate | High (in large-scale projects) |

| Ideal Use Cases | Buildings, safety systems | Utilities, long-distance runs |

Final Thoughts

Both copper and aluminum cables have their place in UAE construction and infrastructure development. The key is to match the material to the projects electrical load, environmental exposure, and long-term maintenance needs.

Collaborating with an experienced cable supplier in UAE ensures you get expert guidance, certified materials, and support tailored to your specific project. Whether you prioritize durability, efficiency, or ease of installation, the right cable choice will boost the safety and performance of your entire electrical system.

Need help choosing the right cable? Work with specialists who understand UAE conditions and offer custom solutions to meet your exact requirements.