What Are Motorized Caster Wheels? Key Features & Benefits

Learn how motorized caster wheels improve mobility, safety, and productivity in industrial settings. Discover key features, benefits, and expert recommendations.

The Power Behind Motorized Caster Wheels

As automation and smart mobility continue to evolve across industrial environments, so does the demand for efficient, ergonomic, and high-performance transport systems. One innovative solution gaining traction is motorized caster wheels an advanced caster type designed to move heavy equipment with minimal effort.

Whether you're navigating tight spaces in a factory or automating material handling systems, motorized caster wheels can help reduce physical strain, enhance safety, and boost overall productivity. This article explains what motorized caster wheels are, how they work, their key features, and why they are becoming essential in modern operations.

What Are Motorized Caster Wheels?

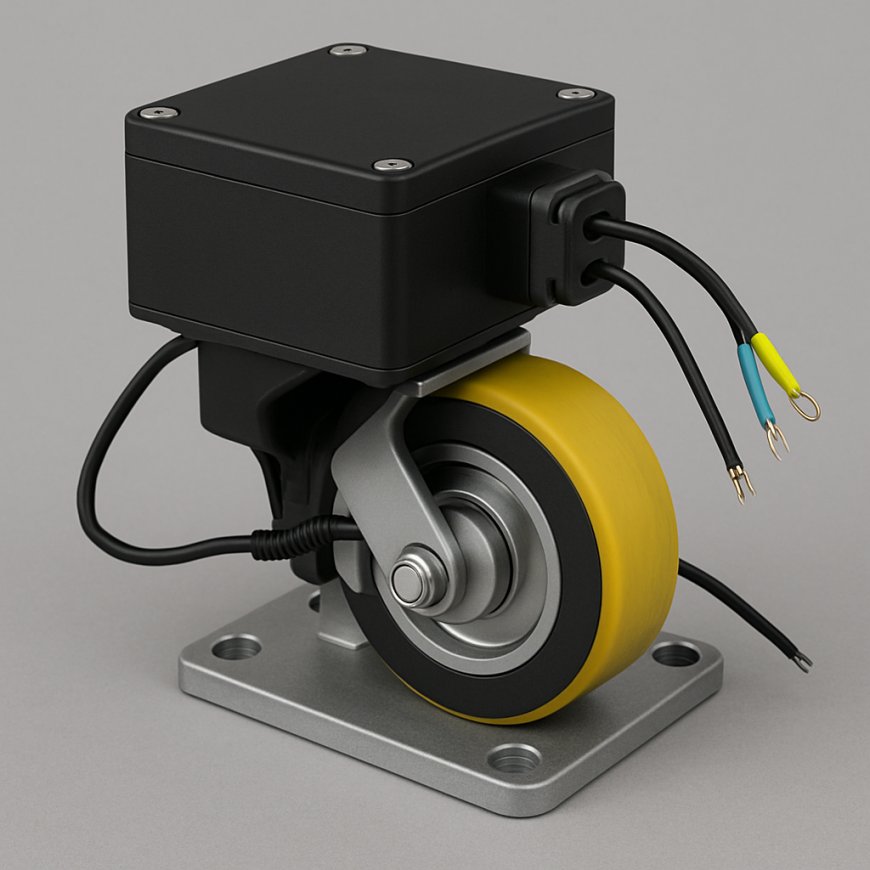

Motorized caster wheels also known as powered casters, drive casters, or electric caster wheels combine traditional caster functionality with electric or battery-powered drive systems. These casters are often integrated into carts, machinery bases, or material handling platforms to provide powered movement in one or multiple directions.

Key Components:

- Drive motor (electric or brushless)

- Control interface (joystick, remote, or integrated system)

- Power source (battery pack or onboard system)

- Caster body (typically steel or aluminum with polyurethane or rubber tread)

Motorized casters allow manual equipment to become powered and semi-automated, reducing reliance on forklifts or manual push-pull labor.

Key Features of Motorized Caster Wheels

1. Powered Mobility

Motorized casters integrate compact motors within the wheel assembly, converting carts or equipment into powered systems. They are ideal for moving loads over long distances or through congested areas without operator fatigue.

2. Variable Speed Control

Modern motorized casters include adjustable speed controls that offer precision maneuverability. This is particularly helpful in production lines, medical labs, or sensitive environments.

3. Direction & Braking Options

Depending on the system, motorized caster wheels can support forward/reverse motion, pivot turning, and regenerative braking for controlled stops.

4. Heavy Load Capacity

Heavy duty drive casters are engineered to support thousands of pounds. When paired with rigid or swivel companions, they allow for seamless transport of large equipment with minimal effort.

5. Custom Drive Caster Options

Need casters to fit a specific application? Custom drive casters can be tailored for mounting patterns, torque specs, environmental conditions, and integration with automated systems.

Applications of Motorized Casters in Industry

1. Manufacturing & Assembly

Industrial drive casters help move heavy fixtures, jigs, or tool carts between stations without manual pushing reducing worker strain and downtime.

2. Healthcare & Laboratories

In cleanroom or hospital environments, electric caster wheels are used for transporting equipment silently and with precision.

3. Aerospace & Defense

Heavy duty powered casters are often installed on maintenance stands, fixtures, and platforms that require controlled movement of heavy, sensitive components.

4. Automated Material Handling

Paired with AGVs (Automated Guided Vehicles) or robotic systems, motorized caster wheels enhance throughput and reduce operational costs in distribution centers and warehouses.

Benefits of Motorized Caster Wheels

- Ergonomic Efficiency: Reduces manual force, improving operator safety

- Precision Control: Great for delicate environments and tight maneuvering

- High Load Capacity: Capable of moving several thousand pounds

- Versatile Mounting Options: Works on carts, fixtures, equipment bases, and platforms

- Battery Powered Flexibility: No need for external power cords or infrastructure

Materials and Construction: Built for Demanding Environments

Most motorized caster wheels feature:

- Steel housings for structural integrity

- Polyurethane or rubber treads for floor protection and quiet operation

- Sealed bearings for smooth rolling under heavy loads

- Integrated motors with thermal protection and overload safeguards

These components ensure durability in harsh industrial environments, including high-moisture or chemical-exposed areas.

Top Manufacturers of Motorized Caster Wheels

When sourcing motorized caster wheels, its crucial to work with a manufacturer that combines innovation with real-world experience. Leading U.S.-based companies in this space specialize in:

- Custom-engineered solutions tailored to specific motion and load requirements

- Rigorous load testing and precision manufacturing standards

- Seamless integration of powered casters into industrial systems and automation workflows

These top manufacturers serve a wide range of industries including aerospace, healthcare, automotive, and logistics by delivering heavy duty drive casters and custom drive casters that meet the most demanding performance criteria. Their focus on durability, safety, and long-term reliability positions them as trusted partners in advanced mobility solutions.

FAQ: Motorized Caster Wheels

Whats the difference between motorized and powered casters?

These terms are often used interchangeably. Both refer to caster systems with integrated motors to drive motion rather than relying on manual force.

Can motorized caster wheels handle heavy machinery?

Yes, heavy duty motorized caster wheels are specifically designed for large equipment and industrial use. Some can handle upwards of 10,000 lbs.

Are custom motorized caster solutions available?

Absolutely. Top manufacturers offer custom drive casters built to your exact specs including size, voltage, control system, and environmental resistance.

Conclusion: Is a Motorized Caster the Right Fit for You?

If your operation demands enhanced mobility, reduced manual effort, and improved safety, motorized caster wheels are worth serious consideration. Their ability to move heavy loads with precision and ease makes them a smart investment in todays fast-moving industrial environments.

Explore options with trusted manufacturers and choose the configuration that best fits your needs whether it's a standard power caster or a custom engineered drive wheel for a complex system.