Roofing Machines: Essential Equipment for Efficient Roof Installation

Explore how roofing machines enhance installation speed, precision, and safety—essential tools for modern contractors aiming for efficient roofing projects.

In the ever-evolving construction industry, roofing has seen significant advancements not only in materials but also in the tools and machinery used to install them. Roofing machines are at the forefront of this evolution, transforming the way contractors and builders approach roof installation projects. These machines not only enhance productivity but also ensure greater precision, consistency, and safety on the job site.

What Are Roofing Machines?

Roofing machinesare specialized equipment designed to automate or streamline specific tasks involved in the installation of roofing systems. These machines significantly reduce manual labor and increase the speed and accuracy of the job.

They can handle everything from:

-

Metal panel forming

-

Seam closing

-

Underlayment application

-

Shingle cutting

-

Gutter forming

-

And even the roof panel lifting

In commercial and industrial roofing, especially metal roofing, machines are not a luxurythey are a necessity.

Types of Roofing Machines

There are several types of roofing machines, each designed for specific tasks. Heres a breakdown of the most common ones:

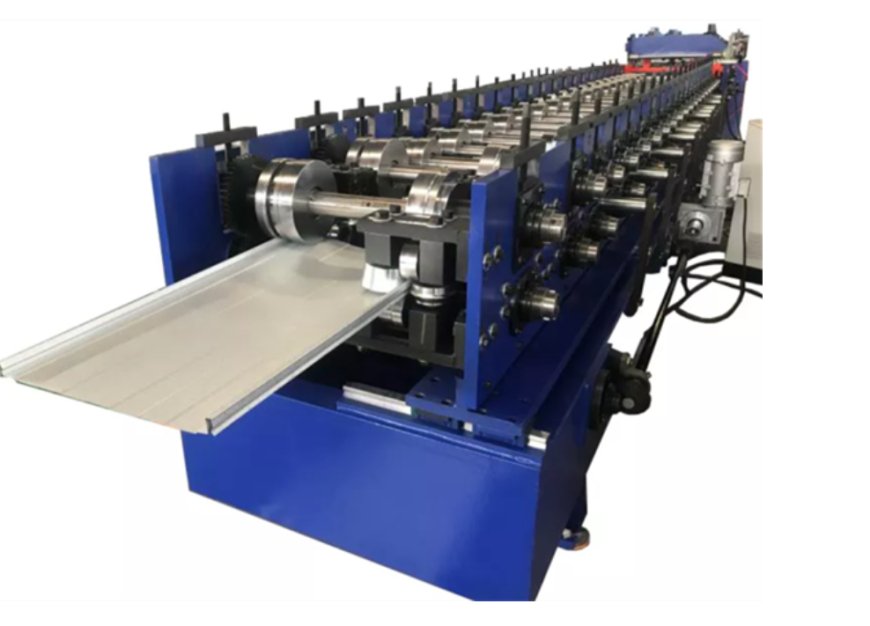

1. Roll Forming Machines

These machines take flat metal coils and transform them into roof panels of various profiles (like standing seam, corrugated, or trapezoidal). Roll forming is precise and allows for custom lengths on-site, reducing waste and saving time.

2. Seam Closing Machines (Seamers)

For standing seam metal roofs, seamers are used to mechanically close and seal the seams between panels. This ensures watertight integrity and speeds up the process compared to manual crimping.

3. Panel Curving Machines

Used when roofing designs call for curved metal panels (common in modern architectural designs), these machines form gentle or tight curves without damaging the panel finish.

4. Gutter Machines

Although not for the roof deck itself, gutter machines form seamless gutters on-site to match the custom roof configuration. Theyre a vital part of a complete roofing system.

5. Shingle-Cutting Machines

These tools allow for precise cuts in asphalt shingles, improving speed and reducing waste on steep-slope roofing projects.

6. Hoisting and Lifting Equipment

Roof panel lifts, cranes, and hoists safely move heavy materials to the roof deck. This reduces manual strain and improves site safety.

7. Hot Air Welders (for Membrane Roofing)

These machines weld seams in TPO or PVC roofing membranes used in flat roof systems. They provide consistent and reliable seam bonding, far superior to manual methods.

Benefits of Using Roofing Machines

Using the right roofing machines offers a host of benefits, including:

1. Increased Efficiency

Machines automate repetitive and labor-intensive tasks, significantly reducing project time. A roll-forming machine, for example, can produce custom panels in minutes.

2. Better Accuracy and Consistency

Manually cutting or bending materials often leads to inconsistencies. Machines provide exact specifications and repeatability, leading to better-looking, longer-lasting roofs.

3. Cost Savings

Although the upfront cost of machines can be high, they reduce labor costs, material waste, and rework. Over time, the investment pays for itself.

4. Improved Safety

Heavy lifting, working at heights, and manual cutting pose injury risks. Machines help reduce the need for these dangerous activities.

5. On-Site Customization

With portable roll formers and gutter machines, contractors can fabricate materials right at the job site, adapting quickly to changes or custom specs.

Key Features to Look for in Roofing Machines

When choosing a roofing machine, keep these features in mind:

-

Portability Especially important for job sites with limited access.

-

Power Source Options include electric, gas, or hydraulic; choose what works best for your setup.

-

Profile Compatibility Make sure the machine supports the specific panel or seam profile you use.

-

Ease of Use Machines with user-friendly controls reduce training time.

-

Durability Construction-grade build quality is crucial for long-term use in tough conditions.

-

Maintenance Support Choose manufacturers who offer reliable service, parts, and support.

Top Applications of Roofing Machines

Roofing machines are widely used across different sectors and roofing systems:

Commercial and Industrial Roofing

-

Standing seam metal roofing

-

Flat roofs with membrane systems

-

Large-scale panel production on-site

Residential Roofing

-

Metal roofs for modern homes

-

Shingle roofing systems

-

Custom gutters for water drainage

Agricultural and Rural Buildings

-

Metal barns and sheds

-

Grain storage structures

-

Livestock shelters

Should You Buy or Rent Roofing Machines?

This depends on your business model and volume of work.

Buy If:

-

You have frequent metal roofing jobs

-

You want to maintain full control over timelines

-

You aim to reduce long-term costs

Rent If:

-

Your usage is occasional

-

Youre testing new roofing systems

-

You want to reduce capital investment

Many machine manufacturers also offer lease-to-own or financing options, which can be a smart middle ground.

Maintenance and Safety Tips

To get the most out of your roofing equipment, follow these best practices:

-

Regularly clean and lubricate moving parts

-

Inspect for worn or damaged components

-

Train your crew on safe and proper usage

-

Keep backup parts on hand to minimize downtime

-

Follow manufacturer guidelines for storage and care

Proper maintenance not only prolongs machine life but also ensures project safety and performance.

Leading Manufacturers of Roofing Machines

If youre in the market for high-quality roofing equipment, here are a few well-known brands:

-

Englert

-

New Tech Machinery (NTM)

-

Roll Former Corp

-

Schlebach

-

Zimmerman Metals

-

CIDAN Machinery

Always consider after-sales support, availability of parts, and training resources when selecting a supplier.

The Future of Roofing Machines

As technology evolves, roofing machines are getting smarter. Some modern machines now feature:

-

Touchscreen controls

-

Digital measurements and diagnostics

-

Remote monitoring and control

-

Better fuel efficiency or battery-powered systems

The integration of automation and smart tech will continue to drive innovation in the roofing sector, making installations faster, safer, and more sustainable.

Conclusion

Roofing machines have revolutionized the way roofs are installed and maintained. They bring precision, speed, and reliability to a trade that has historically relied on manual labor. Whether youre a small roofing business or a large contractor, investing in the right equipment can give you a major edge in todays competitive market.