How PCB Suppliers Shape the Future of Electronics

PCB suppliers are much more than vendors. They are strategic partners who enable innovation, ensure reliability, and help shape the technological future.

In the modern world of rapid technological advancement, printed circuit boards (PCBs) are the silent heroes powering virtually every electronic device. From smartphones and laptops to medical devices and autonomous vehicles, PCBs form the backbone of all electronic systems. But behind the brilliance of these innovations are the often-overlooked enablersPCB suppliers. Their role is not just about manufacturing boards; its about driving innovation, ensuring quality, and shaping the future of electronics.

If youve ever wondered why some gadgets outperform others or how groundbreaking electronic designs come to life, its time to take a closer look at the pivotal role of PCB suppliers. Find out more about their impact below.

The Backbone of Electronics: Understanding PCBs

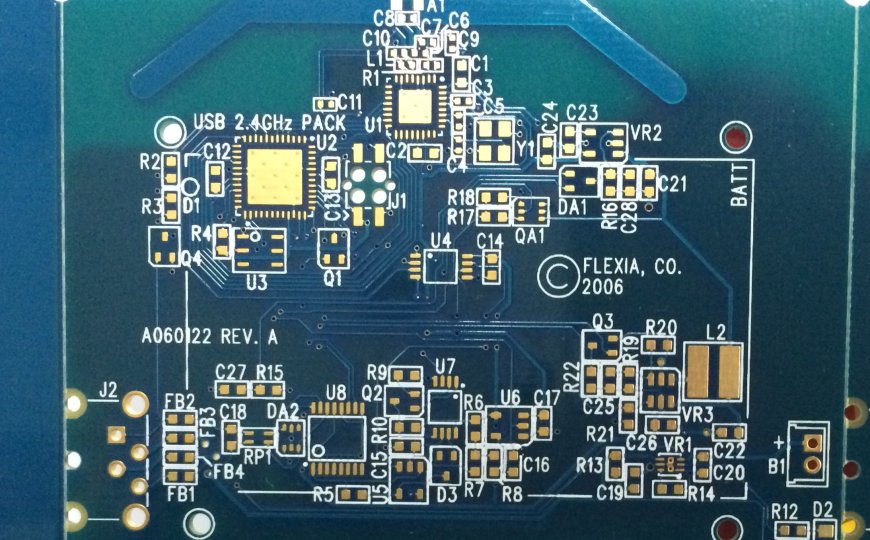

A printed circuit board mechanically supports and electrically connects electronic components using conductive pathways. These pathways, etched from copper sheets laminated onto a non-conductive substrate, allow signals and power to flow between components.

From single-layer boards used in simple devices to complex multi-layer PCBs found in advanced aerospace systems, the design and quality of the PCB can make or break the final product. And this is where PCB suppliers step in.

The Crucial Role of PCB Suppliers

1. Innovation Enablers

Innovation in electronics starts with the design stage. PCB suppliers who invest in research and development contribute significantly to technological breakthroughs. For example, as consumer electronics demand smaller, faster, and more powerful devices, suppliers respond by offering:

- High-density interconnect (HDI) PCBs for compact and complex circuits

- Flexible and rigid-flex PCBs for wearable technology and aerospace

- High-frequency PCBs for 5G and high-speed data transfer

Without forward-thinking suppliers who push boundaries, manufacturers would struggle to innovate.

2. Customization and Prototyping

Leading PCB suppliers offer highly customizable services, allowing engineers and designers to test and refine their products. Fast-turn prototyping is critical for startups and established firms alike. It enables:

- Rapid iterations of electronic products

- Early detection of design flaws

- Faster time to market

If you're looking to collaborate on an electronic product, a supplier offering rapid prototyping can be a game changer. Check over here for some of the top industry players offering quick turnaround services.

Quality Assurance and Compliance

In sectors like medical electronics, automotive systems, and aerospace, the margin for error is zero. A poorly manufactured PCB can cause catastrophic failures. Top-tier PCB suppliers ensure:

- Strict adherence to industry standards such as IPC-A-600, ISO 9001, and UL

- Rigorous quality control through automated optical inspection (AOI), X-ray inspection, and in-circuit testing

- Compliance with environmental and safety regulations, such as RoHS and REACH

This attention to quality helps build reliable, long-lasting electronic products.

Supply Chain Optimization

In the era of globalized production, managing a robust supply chain is critical. Suppliers not only manufacture PCBs but also play a role in:

- Material sourcing: Selecting high-quality substrates, copper foils, and laminates

- Logistics and delivery: Ensuring timely shipping, which affects production schedules

- Inventory management: Offering just-in-time (JIT) delivery systems for efficient assembly

A reliable PCB supplier reduces delays, mitigates risks, and improves overall production efficiency. If your company is scaling and needs consistency in supply, go right here to discover how professional suppliers manage logistics and customer support.

Technological Adaptability

The technology landscape evolves constantly. Whether its the rise of the Internet of Things (IoT), electric vehicles (EVs), or AI-driven hardware, PCB suppliers must keep pace.

Examples of Technological Adaptability:

- IoT Devices: Require miniaturized PCBs with wireless capabilities.

- EVs and Renewable Energy Systems: Need PCBs capable of handling high current and temperature ranges.

- Consumer Electronics: Demand ultra-thin, multi-layer boards with aesthetically pleasing layouts.

By investing in state-of-the-art machinery like laser direct imaging (LDI), advanced drilling techniques, and AI-based quality inspections, suppliers stay ahead of the curve and empower their clients to do the same.

Sustainability and Green Manufacturing

Environmental concerns are reshaping industries worldwide, and electronics are no exception. Reputable PCB suppliers are increasingly focused on sustainable practices, such as:

- Reducing waste: Through precision manufacturing and efficient use of materials

- Recycling: Employing systems to recover and reuse copper and other materials

- Eco-friendly chemicals: Using safer alternatives in the etching and cleaning processes

Companies that care about their environmental impact should partner with suppliers that align with their green values. To learn how to identify eco-conscious partners, find out more about sustainability certifications in PCB manufacturing.

Supporting Startups and SMEs

While large corporations often dominate headlines, the future of electronics also lies in the hands of startups and small to medium enterprises (SMEs). Forward-thinking PCB suppliers provide:

- Affordable prototyping

- Flexible minimum order quantities (MOQs)

- Technical support and design consultation

This support lowers the barrier to entry for entrepreneurs and inventors who are creating the next generation of smart devices, wearables, and automation systems. If you're launching a hardware startup, check over here for suppliers that cater specifically to emerging businesses.

Global Reach and Local Service

The best suppliers strike a balance between global capabilities and local service. While some companies benefit from overseas manufacturing for cost efficiency, others prefer domestic suppliers for better communication and faster delivery.

Todays PCB suppliers often maintain:

- Global manufacturing hubs in Asia, Europe, and North America

- Local sales and support teams for real-time customer engagement

- Multilingual service and 24/7 technical assistance

Whether youre a multinational corporation or a local tech startup, choosing a supplier with global reach and localized support is crucial. Go right here to explore case studies of companies benefiting from this hybrid model.

The Future Outlook: Smart, Connected, and Autonomous

Looking ahead, the demand for PCBs is expected to grow exponentially. Emerging technologies will further shape the capabilities and expectations of PCB suppliers, including:

- AI-integrated PCBs: For machine learning at the edge

- Bio-compatible PCBs: For implantable medical devices

- Optoelectronic PCBs: For faster data transmission using light

To stay relevant, suppliers will need to adopt digital manufacturing, predictive analytics, and smart factories. As Industry 4.0 becomes the norm, suppliers will play a transformative rolenot just as manufacturers, but as collaborators and co-innovators.

Final Thoughts

PCB suppliers are much more than vendors. They are strategic partners who enable innovation, ensure reliability, and help shape the technological future. Whether youre designing a next-gen consumer device or developing mission-critical aerospace hardware, choosing the right supplier can make all the difference.

Ready to explore the cutting edge of PCB technology? Find out more, check over here, or go right here to connect with industry leaders who are driving change and powering progress.